In brief

Spiral heat exchangers for contaminated or fibrous media

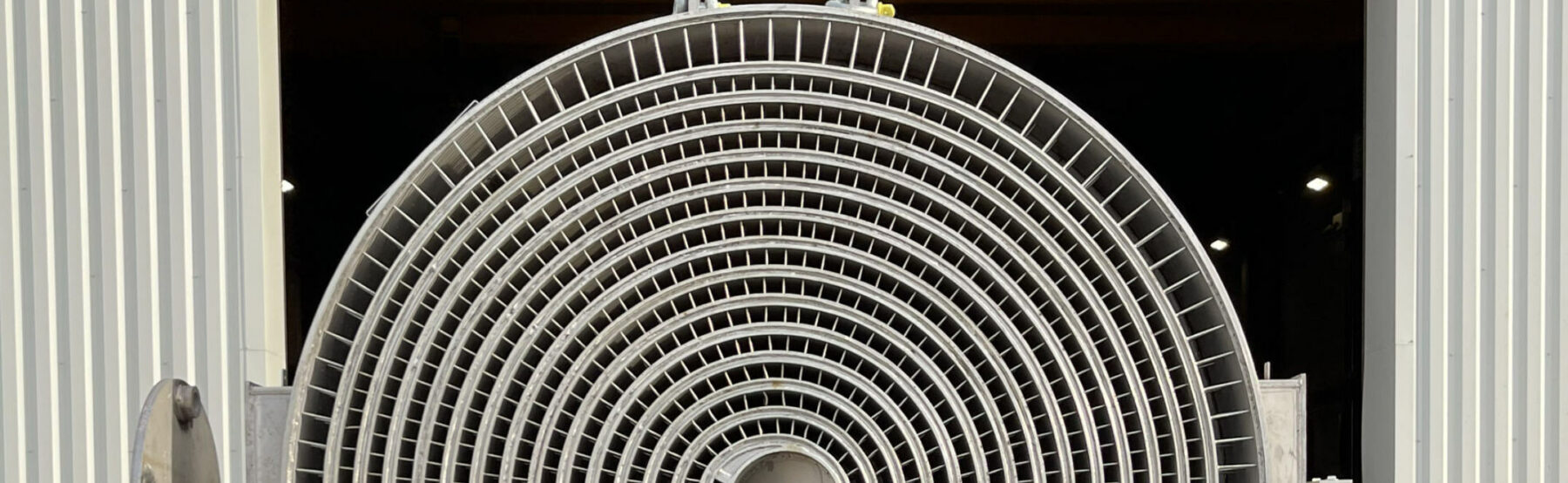

If the medium in an application is contaminated or fibrous, a tubular heat exchanger may be effective, but if two such media are involved in the heat exchange, this technology may not suffice. In contrast, a spiral heat exchanger, designed specifically as a liquid-to-liquid heat exchanger, can handle one or two foul/fibrous media. The two channels of the spiral heat exchanger are easily accessible for cleaning and inspection. Moreover, a spiral heat exchanger provides a significantly better temperature approach than a tubular heat exchanger. With three decades of experience in designing and manufacturing heat exchangers, pressure vessels, and filters, the Nexson Group can offer solutions for a wide range of processes and applications.

Compact and robust technology

Suitable up to 200 barg / 450°C. For liquid-liquid applications, one Nexson spiral heat exchanger can replace three traditional shell & tube heat exchangers.

Easy access for inspection and cleaning

The end plates, fitted with hinges, function as doors, and facilitate access, inspection, and cleaning of the entire heat transfer surface.

About Nexson

Proven technology for difficult applications

Nexson, located in the heart of Burgundy, France, specializes in the design, development, and manufacturing of spiral heat exchangers using various mouldable and weldable materials. With more than three decades of experience, Nexson possesses extensive expertise in various processes. The spiral heat exchanger technology was patented in 1930 and was initially employed for pulp and paper applications with high pollution levels. Since 2011, the API664 standard for the petroleum industry has covered the spiral heat exchanger.

“We understand that time is precious, which is why our heat exchangers are designed for easy maintenance and cleaning”

Nexson’s spiral heat exchangers offer an ideal solution for demanding applications that involve wastewater, sludge, slurries, pollutants, and high-viscosity liquids. These heat exchangers are specifically designed to provide easy maintenance and cleaning, saving precious time. The hinged lids allow for simple access to the entire heat transfer surface.

Products

Compact and efficient heat exchangers for contaminated media

Thanks to its thermal efficiency, power and versatile design, the spiral heat exchanger has proved indispensable in diverse sectors such as refineries, petrochemicals, oil and gas or environment since 1930 and withstands extreme conditions (pressure and temperature). This single channel heat exchanger, with self-cleaning effect, is the solution for applications with two contaminated media, where a Shell & Tube heat exchanger is not suitable. The spiral heat exchanger is more compact and 2 to 3 times more thermally efficient than tube heat exchangers, and delivers significant savings in installation, operation, and maintenance.

Liquid-liquid spiral

Thanks to its specific design, this liquid-liquid heat exchanger can handle one or two contaminated fluids. Both channels are easily accessible for inspection and cleaning.

Two-stage spiral

In this type of heat exchanger, the vapour circulates, crosswise, in a completely open channel. The refrigerant circulates in a closed spiral channel. Perfectly suited for vacuum condensation.

Steam heater

This configuration is commonly used to heat a contaminated, viscous liquid using steam. The steam circulates in an open channel and the heavy liquid circulates in a spiral channel.

QUALITY REQUIREMENTS

We demand the same high quality as you

Nexson and Kapp are familiar with the critical questions and stringent requirements from industry. All our products meet or can be supplied to design requirements and standards relevant to the industry you work in. These include:

Design codes

- ASME VIII, Div. 1

- EN 13445

- PD550

- ATEX

Quality standards

- ISO 9001:2015

- API664

- ASME U and R Stamp

- NB Certificate

- EcoVadis