Compact cooling solution for pump bearings

A pump inevitably loses efficiency due to friction in its bearings. This friction generates heat that must be dissipated to keep the pump running continuously and prevent overheating. One of our regular clients, an infrastructure specialist supporting the energy transition by installing district heating networks, was therefore looking for a compact and sustainable cooling solution. The challenge was limited space and no supplier willing to go beyond standard products, while a standard solution simply would not fit. Exactly the kind of problem that energizes Kapp.

Smart customization

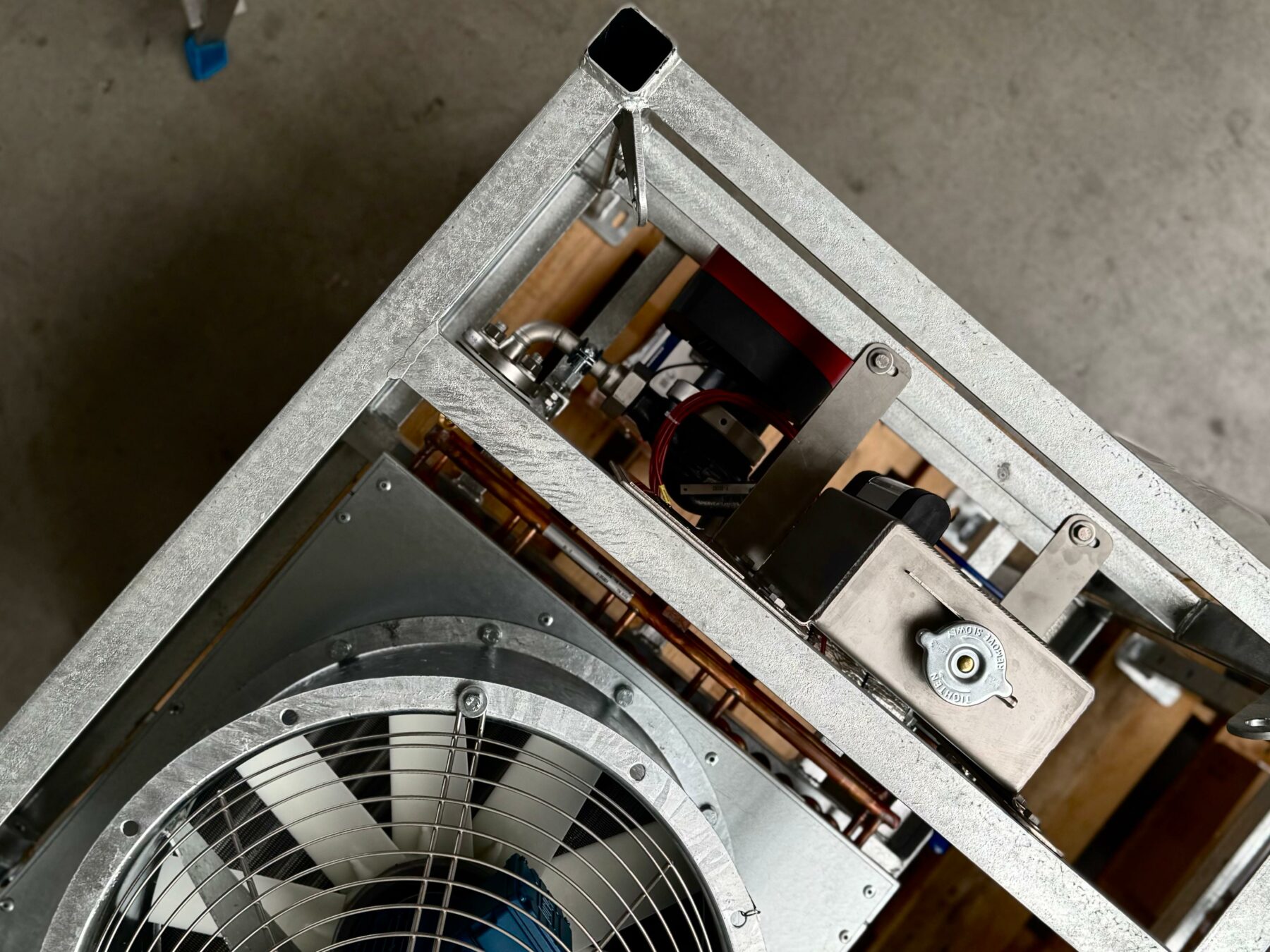

We designed and built four fully customized air-to-water cooling kits, compact enough to fit into the tight space of an existing machine room. One strict requirement guided our design: no unnecessary use of drinking water or energy. That’s why we chose air cooling over water cooling, providing 14 kW of cooling capacity without consuming a single liter of drinking water. A frequency-controlled fan ensures optimal energy efficiency.

Pragmatic approach

Where standard solutions fell short, our pragmatic approach made a fully tailor-made solution possible. The customer particularly appreciated that we contributed ideas proactively instead of relying solely on catalog products. The result is a robust, maintenance-friendly cooling system with easily replaceable components, designed to provide maximum operational reliability, ease of use, and sustainability from the moment it is commissioned.

Talk to our specialists

Want to know more about this project? Curious about what we can do for your situation?

Kevin can answer all your questions!