From residual waste to returns: Kapp supplies vent condenser for waste-to-energy company

The energy transition calls for smart solutions, where making optimal use of raw materials and energy sources is key to building an efficient and sustainable future. Kapp is supplying a vent condenser (also known as a partial condenser) for a new waste-to-energy project for a waste processing company in the Czech Republic. This installation converts residual waste into usable energy while significantly reducing CO₂ emissions. We’re happy to explain how!

“There’s some air in the steam, does that matter?”

Is steam just steam?

In waste-to-energy plants, steam is a logical energy carrier. But in practice, this steam is rarely pure. A frequently asked question is: “There’s some air in the steam, does that matter?” The answer is an emphatic yes. While pure water vapor remains at a constant temperature during condensation, the presence of non-condensable gases (such as air) causes a temperature drop. This disrupts the condensation process, leading to the loss of valuable energy and inefficient system operation. Kapp’s challenge was to achieve effective condensation of this impure steam within an existing installation, constrained by limited space, demanding process conditions, and strict integration requirements. The goal of the project was to achieve maximum heat and water recovery without compromising reliability or performance.

Can residual waste yield returns?

The project is part of this waste processor’s broader energy transition, in which converting residual waste into usable energy contributes to a more sustainable energy mix and reduces landfill waste. Kapp’s philosophy aligns seamlessly with this approach: through smart thermal solutions, we maximize the use of residual energy by recovering heat and water from complex steam and gas streams. In this way, our technology ensures that the waste processing company will comply with strict EU environmental standards and contributes to a circular and energy-efficient energy supply.

Air-Cooled Condensation

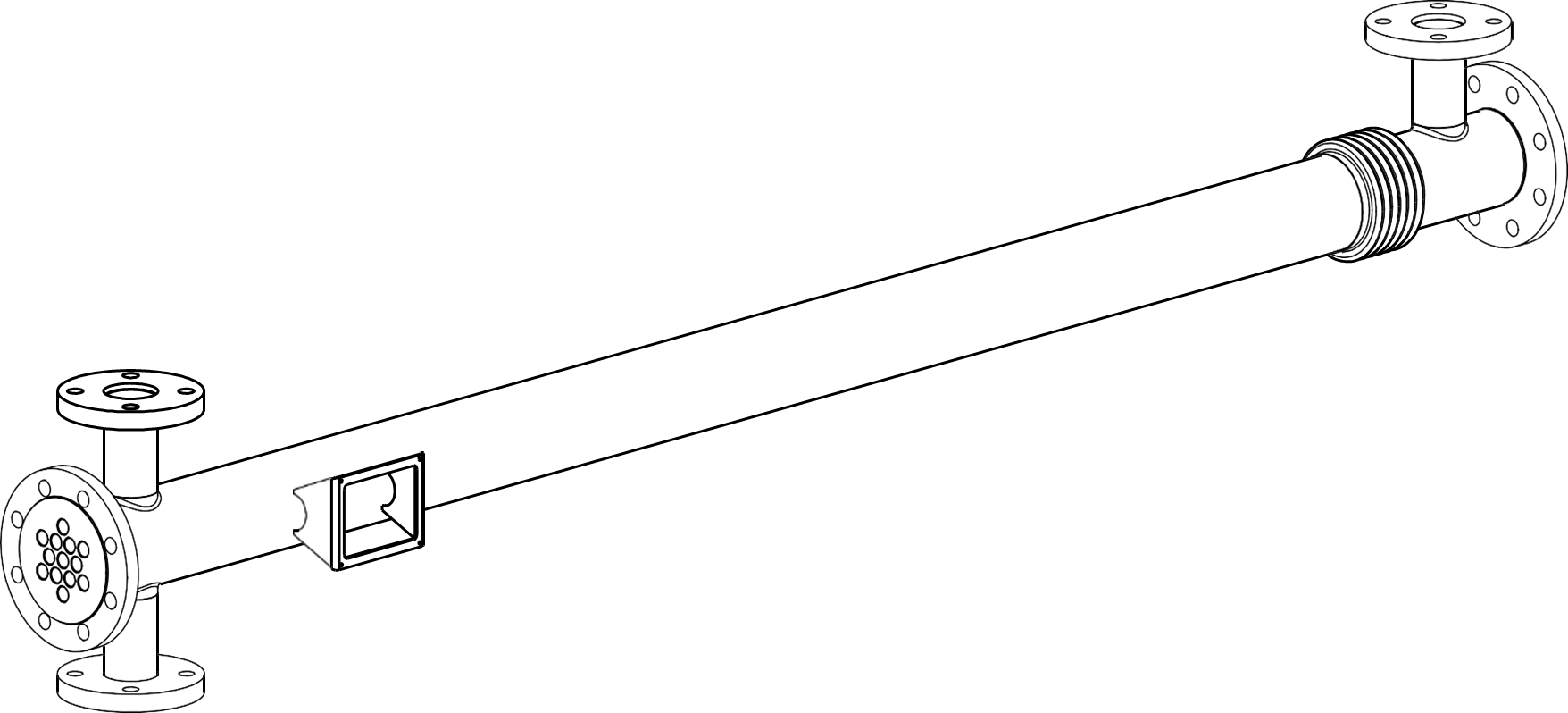

Kapp is supplying a vent condenser for this project: an HRS Heat Exchangers tube heat exchanger that we have specially designed for steam flows with non-condensable gases. The tube exchanger shown below is sized for a vapor consisting of 99.2% H₂O, 0.3% O₂, and 0.5% N₂. A low concentration of non-condensable gases, but process conditions meant that ultimately 10% could not condense. With 100% water vapor, this would have been possible.

The condenser cools and condenses steam and gases, recovering valuable heat and clean condensate. This prevents energy loss and unwanted steam plumes and provides hot water and reusable condensate for reuse in the process. With this solution, Kapp increases the overall energy efficiency of the installation and contributes to a stable and sustainable operating process.

Value from every degree

This case demonstrates that even challenging residual streams, such as impure steam, contain significant value. Through smart thermal engineering, we make industrial applications cleaner and more cost-effective, help industry comply with strict environmental standards, and reduce energy costs.